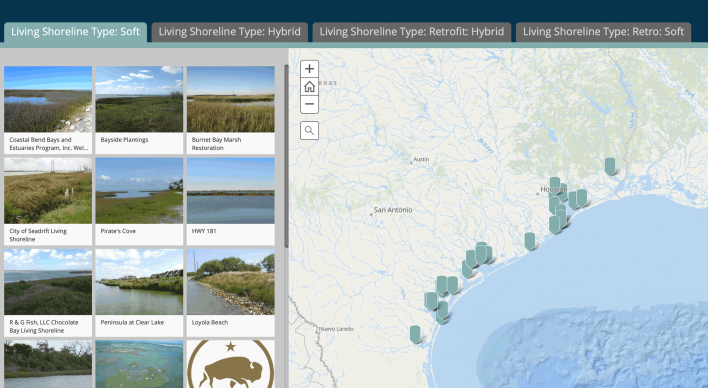

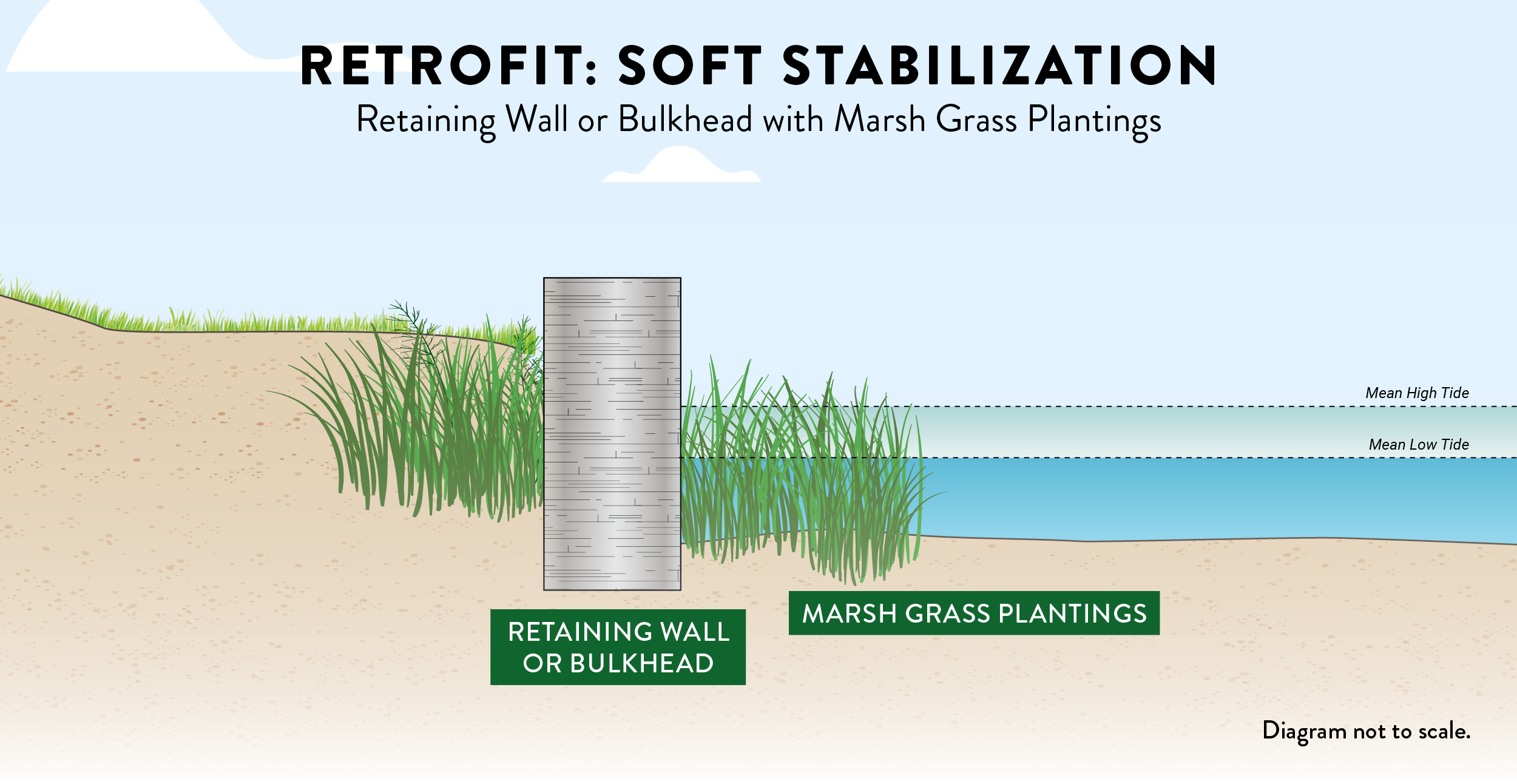

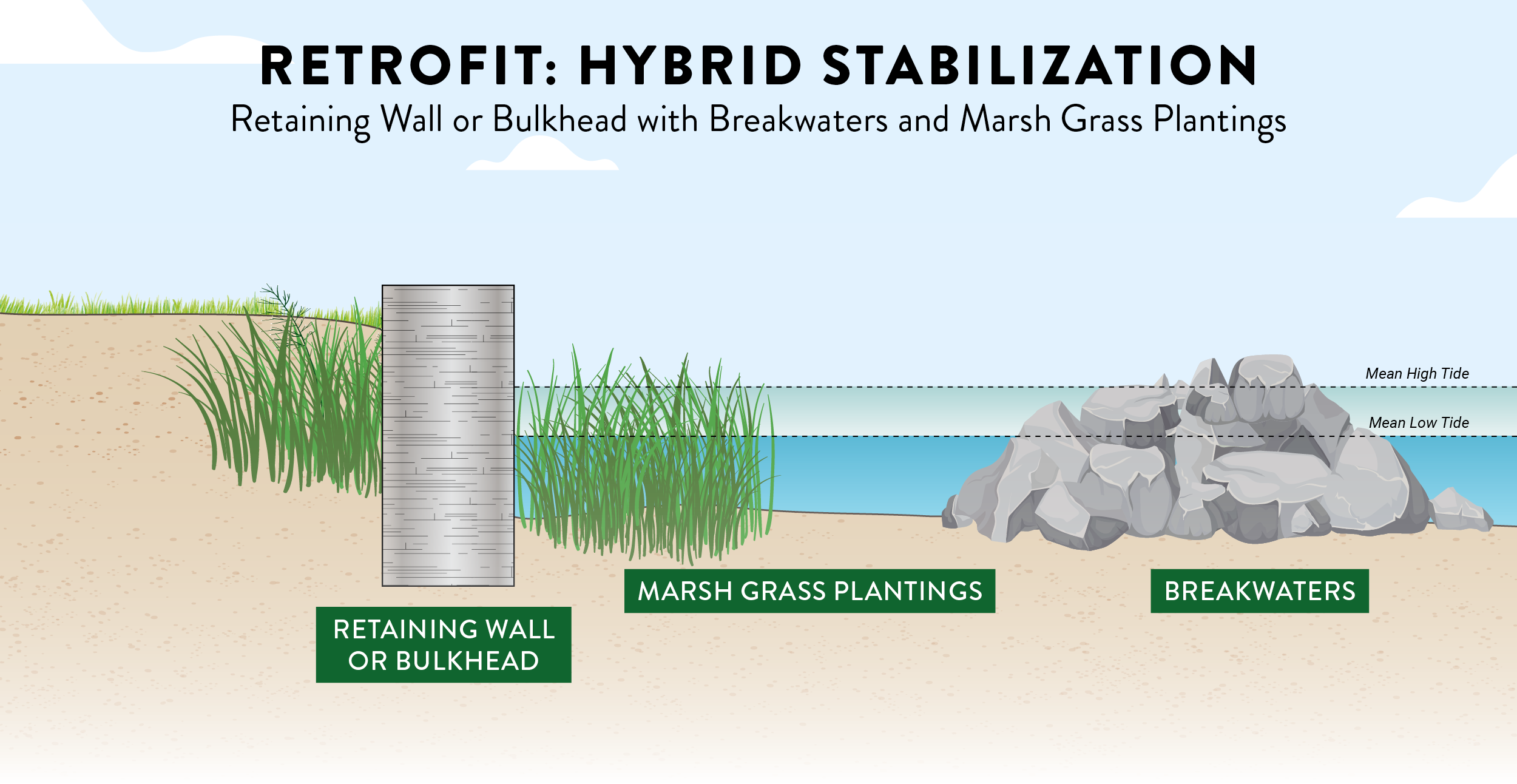

Hybrid stabilization living shorelines incorporate the materials used in soft techniques with hard features to provide additional erosion protection. These structural features complement natural processes and often help the propagation of shoreline vegetation.

HYBRID STABILIZATION OPTIONS

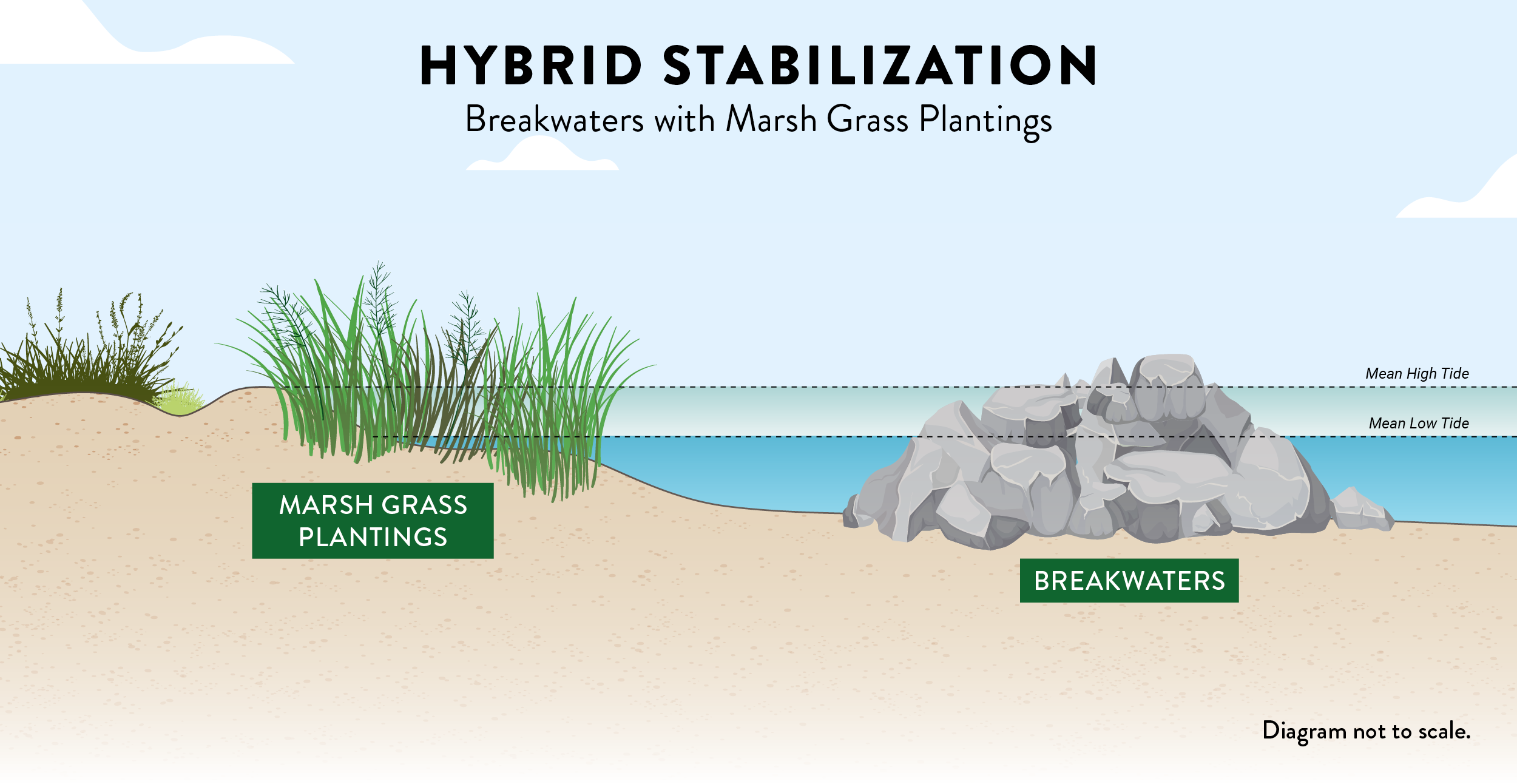

Breakwaters

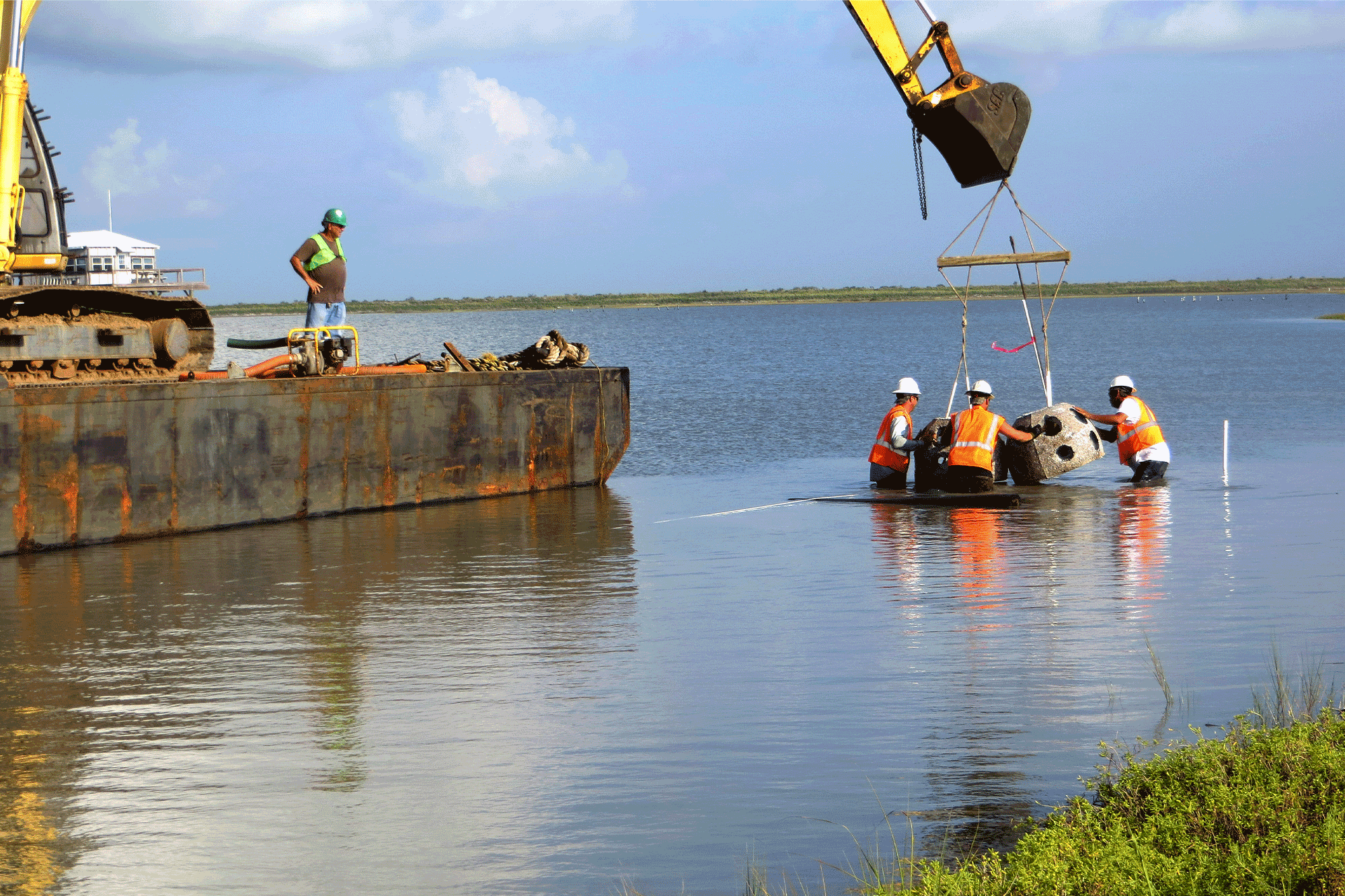

Breakwaters are constructed nearshore, parallel to the shoreline, and function to break waves, reduce erosion, and promote sand and sediment accumulation landward of the structure. Breakwaters can consist of a variety of materials including rock rubble, concrete chunks, precast concrete forms, and reef. Low-profile breakwaters can be constructed in deep water and in high energy wave environments. Low-profile breakwaters, combined with landward marsh grass plantings, reduce wave energy while also providing habitat for plants and animals.

The breakwater structure can serve as habitat for filter feeders, such as oysters, whose presence improves water quality and further helps reduce wave action. Additionally, as sediment accumulates landward of the breakwater, the marsh grass roots anchor and retain the soil, building up the shoreline. The plantings also help dissipate wave energy and reduce erosion. Marsh grass plantings protected by a breakwater maintain a more balanced aquatic/ terrestrial interface and provide recreational and educational opportunities.

SPECIFICATIONS

- Materials: Rock rubble, reef (oyster/mussel shells), concrete chunks, precast concrete forms, or stone. Oyster shell reefs can be constructed with bagged or loose shell. Native marsh plants appropriate for salinity and site conditions should be used. Plugs of marsh grass can be planted in bare or sparse areas. Grading may be necessary to obtain appropriate elevations, to provide a gradual slope for marsh creation, or to enable a marsh to maintain its elevation with respect to sea level rise. Wildlife exclusion fencing may be necessary to avoid predation while plants develop.

- Installation Technique: Low-profile breakwaters can be irregularly shaped or spaced in a specific pattern and involve placing low-profile stone, bagged concrete or man-made structures in the water to break wave energy. Native plants are added in areas of suitable depths to the marsh environment landward of the structure.

- Durability and Maintenance: The degradation of the shell bags is often a desired characteristic if they are being used to temporarily reduce wave energy while marsh grass plantings reestablish or oysters attach to the substrate.

Plants that die during the early stages of the living shoreline project should be replaced immediately to ensure the undisturbed growth of the remaining plants and continued creation of the marsh substrate. Debris removal and selective tree pruning are also good maintenance practices to ensure that sunlight reaches the plantings. Once establishment has occurred, only periodic inspections may be necessary. Low-profile breakwater materials should also be replaced or re-installed if they are moved by a storm.

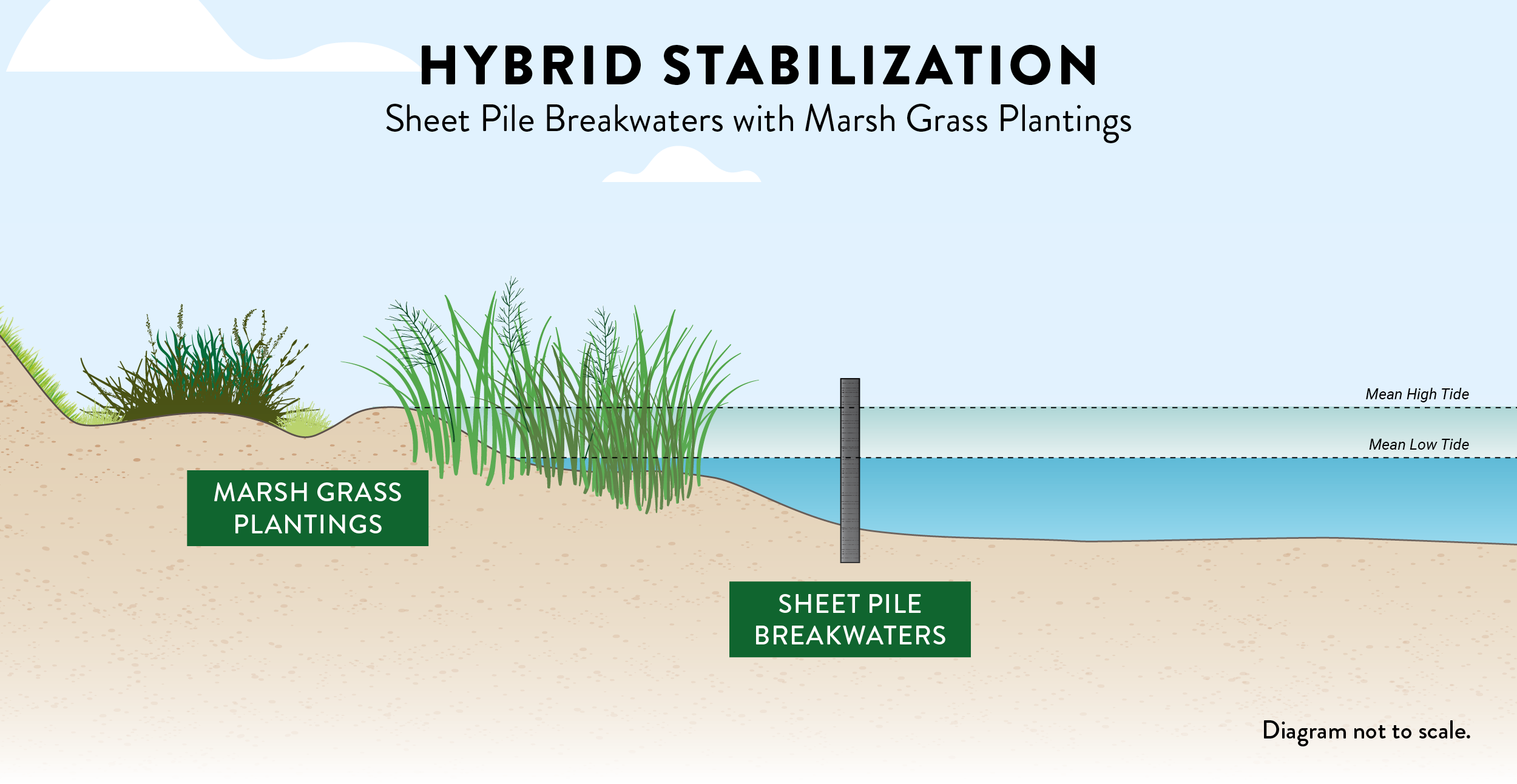

Sheet Pile Breakwaters

Another type of breakwater material is sheet pile or vinyl sheet pile. Sheet pile breakwaters may be made of PVC sheet piling, synthetic sheet piling, vinyl sheet piling, or other sheet piling brand name materials. The vinyl panes are driven into the ground, decreasing wave energy and creating a calmer area landward of the breakwater that promotes vegetative growth.

Though a more affordable material, the two-dimensional shape of a sheet pile breakwater lacks the complex structure necessary to provide habitat. Therefore, a sheet pile breakwater alone is not considered a living shoreline. However, it may be used as part of a larger living shoreline project.

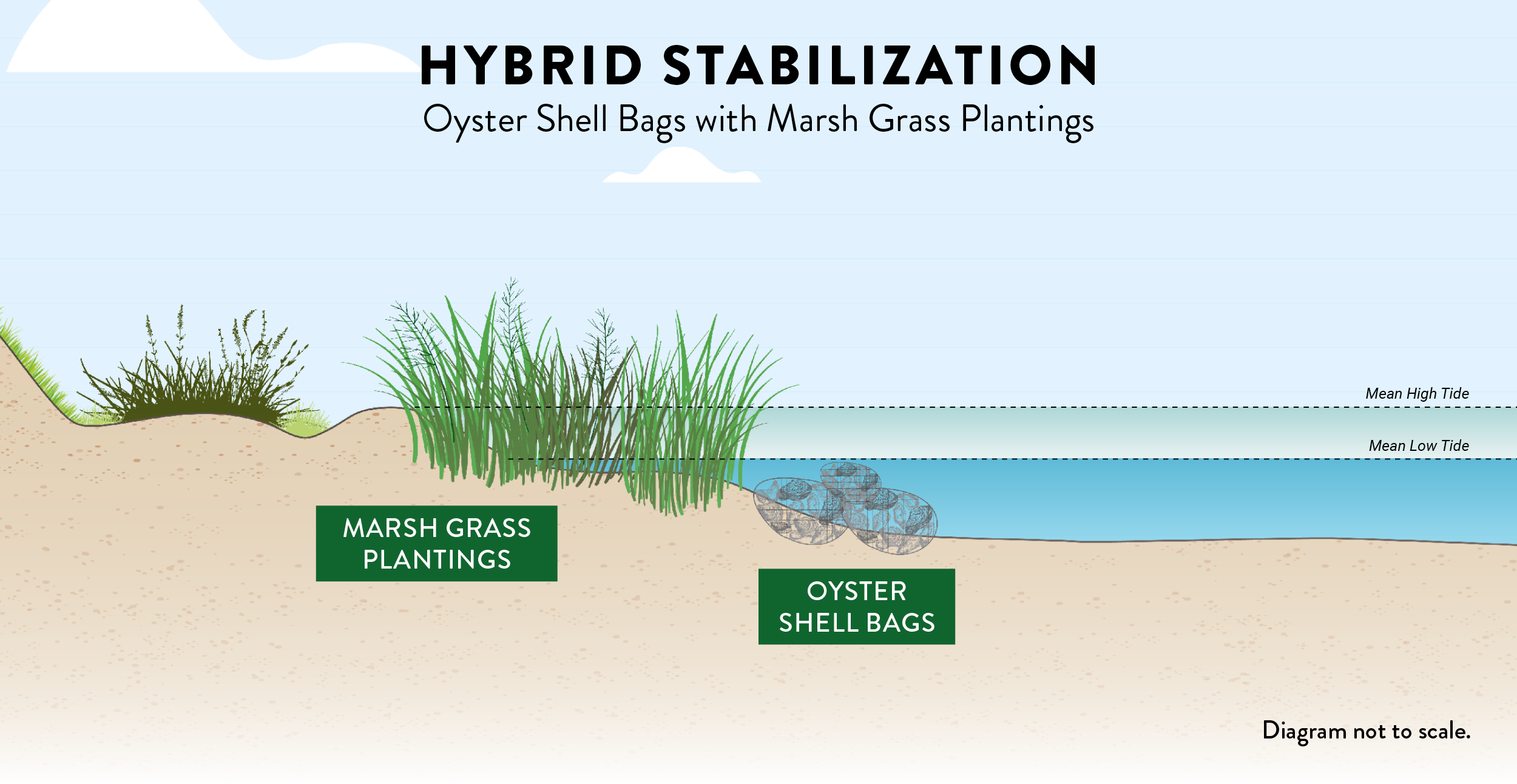

Submerged Oyster Shell Beds

Oyster shell is not commercially available in Texas and must be acquired from an oyster wholesaler. Oyster shell-based living shorelines will primarily be a building option for local governments, community groups, and nonprofit organizations.

SPECIFICATIONS

- Materials: Recycled oyster shells or crushed concrete, limestone, or river rock; oyster bags (bagged oysters) or oyster gabion (cages).

- Installation Technique: Hard substrate is placed on the seafloor and “seeded” with oyster larvae. The larvae attach to the shells or rocks and begin to grow.

- Durability and Maintenance: Oyster shells and/ or crushed concrete are very durable. However, these materials can become covered in sediment due to settling or because of wave-driven sedimentation over time. Changes in environmental factors can lead to die-off of the live oysters, so re-seeding might be required. Routine inspections are necessary and periodic additions of oyster shell or crushed concrete may be required to maintain function.

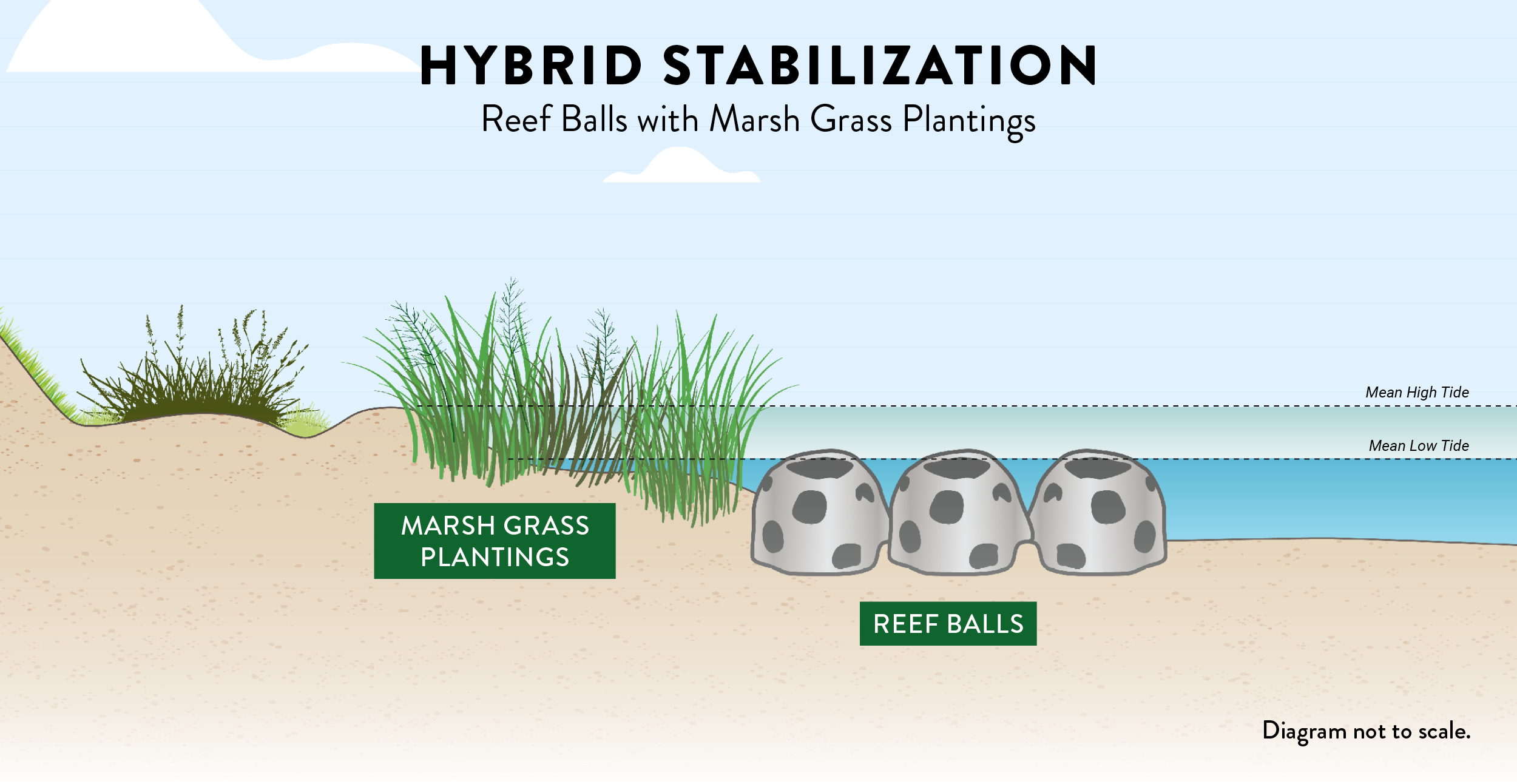

Reef Balls

Reef balls are nearshore structures designed to create oyster and fish habitat while reducing wave energy. These structures can become valuable hosts for marine organisms and provide shelter and habitat for fish, crabs, and other species. By reducing wave energy, the reef balls increase sediment retention for potential marsh creation. As these structures become colonized with marine species, they provide recreational benefits such as fishing and snorkeling.

SPECIFICATIONS

- Materials: Reef balls are made from a pH- balanced concrete poured over fiberglass to create a hollow, porous structure typically in the form of an open-topped dome. The surface is textured to promote the attachment and growth of aquatic organisms.

- Installation Technique: Placed in shallow water environments to create a submerged breakwater. Structures are typically placed at predetermined intervals although space between structures is not always necessary due to the porous design which allows water flow-through.

- Durability and Maintenance: If cited properly, structures are extremely durable due to their design and the materials used in fabrication. Once placed, almost no general maintenance is required. Structures and placement may become altered in significant storm events.

Articulated Blocks or Mats

Articulated blocks or mats alone are not considered a living shoreline, but they may be used as part of a larger living shoreline project. Mats are typically constructed as a flexible, interlocking matrix of concrete blocks that are uniform in shape and size and held together by a series of cables or installed as individual blocks. Articulated blocks or mats can contribute to the ecosystem by allowing vegetation to grow through the crevices, providing erosion control and creating habitat. Articulated mats may also be used in some situations to provide an extra layer of shoreline stabilization and erosion control.

SPECIFICATIONS

- Materials: Prefabricated articulated concrete mats or hand placed blocks.

- Installation Technique: Larger projects covering significant areas may require professional installation and the use of heavy machinery. Smaller projects such as residential shorelines can be installed by hand.

- Durability and Maintenance: If installed properly using anchor systems on shoreline slopes, the structures require very little maintenance and are highly durable. Debris should be routinely removed and plants may need to be periodically replaced.

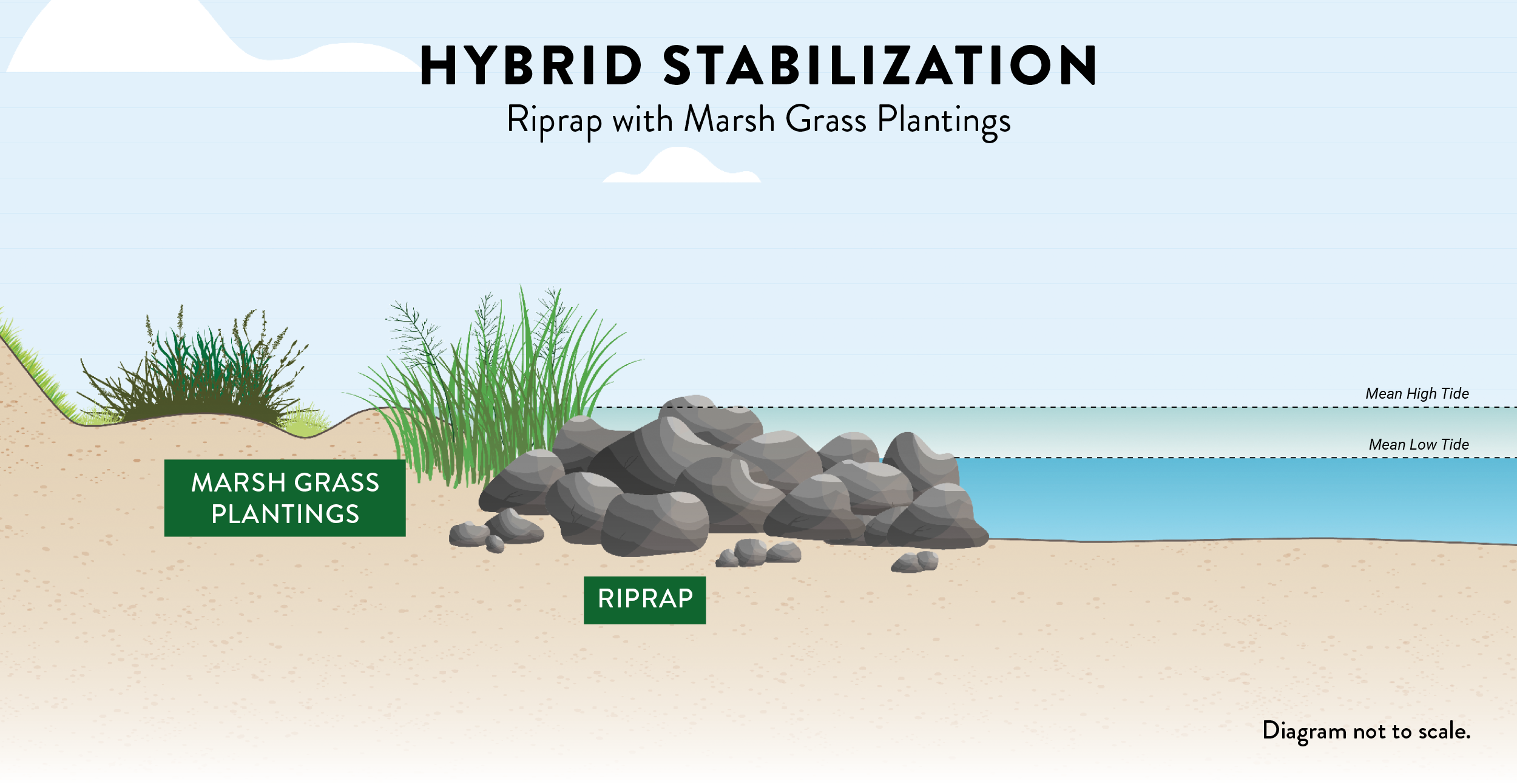

Riprap

Riprap alone is not considered a living shoreline, but it may be used as part of a larger living shoreline project. Riprap, sometimes called a revetment, is placed along the shoreline to break waves and reduce erosion. Riprap consists of stone or concrete of various shapes and sizes depending on the wave action and shoreline length at the project site. The Texas General Land Office only allows a 3:1 ratio of riprap to height of shoreline. For example, a shoreline that is 3 feet above the high-water mark (mean high tide) would be authorized to have a riprap width of 9 feet.

Riprap paired with marsh grass plantings can contribute to the ecosystem by providing habitat for oysters as well as small crab and fish species. It may also be used in some situations to provide an extra layer of shoreline stabilization and erosion control.

SPECIFICATIONS

- Materials: Stone or concrete

- Installation Technique: Riprap is placed along the shoreline at the water-land interface.

- Durability and Maintenance: Riprap is very durable and low maintenance. Tropical storm events may move smaller-sized material. Debris may need to be removed from riprap periodically.